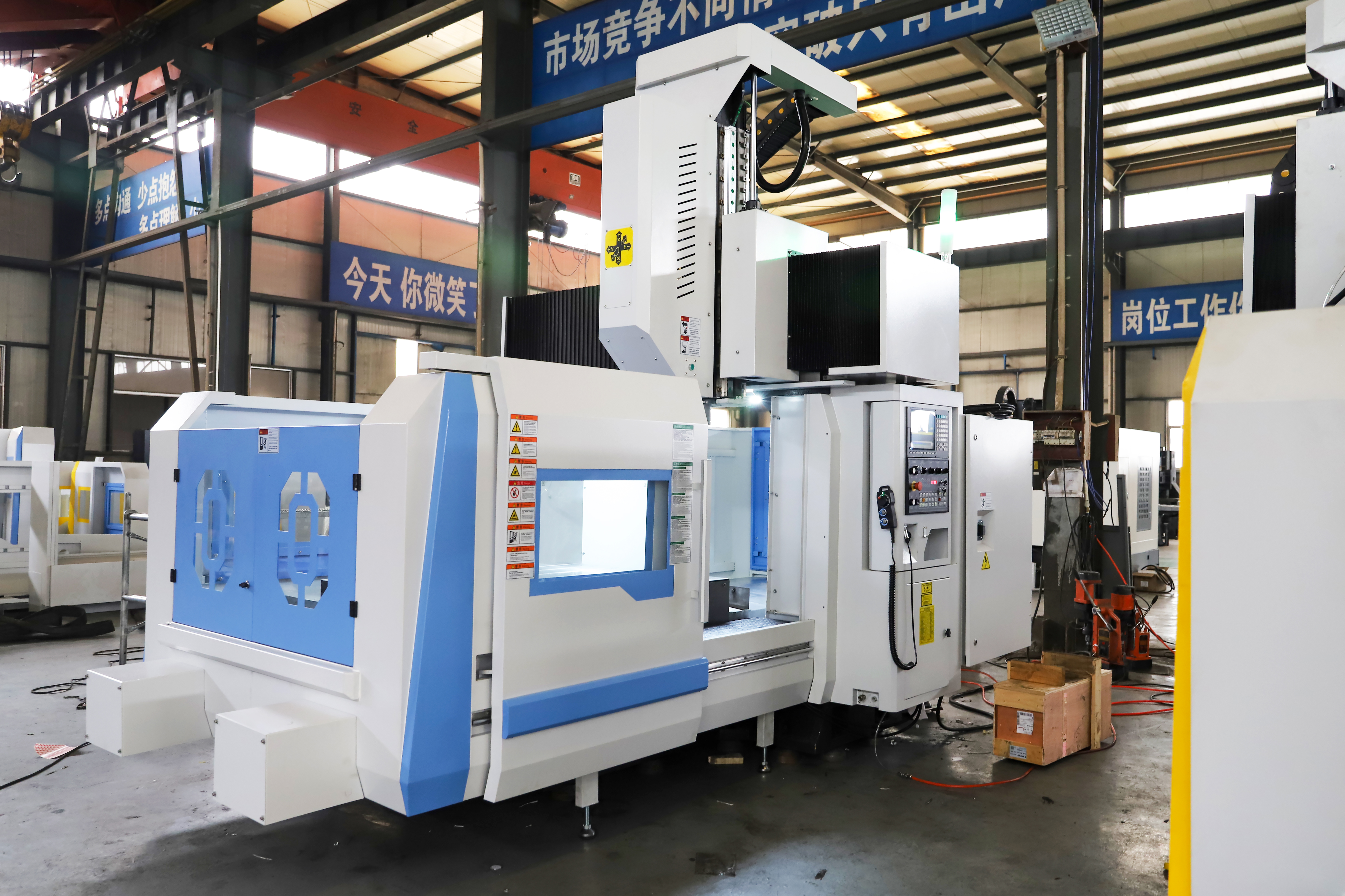

Versatility in Operations and Materials

The versatility of the CNC milling machine makes it an indispensable tool for manufacturers across various industries. With the ability to work with a wide range of materials, including metals, plastics, and wood, the machine can produce a diverse array of products without the need for additional specialized equipment. Furthermore, its capability to execute multiple operations, such as cutting, drilling, and engraving, on a single machine eliminates the need for multiple setups and reduces the risk of human error during the transition between processes. This flexibility is invaluable for businesses looking to streamline their operations, reduce costs, and respond quickly to market demands and design changes.